On Sale

Original price was: $266.00.$126.00Current price is: $126.00.

Original price was: $227.00.$199.00Current price is: $199.00.

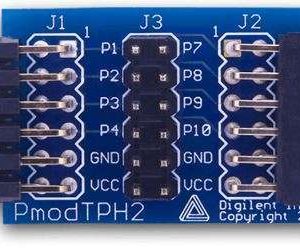

Original price was: $2.50.$1.00Current price is: $1.00.

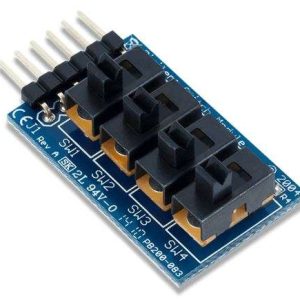

Original price was: $34.50.$9.90Current price is: $9.90.

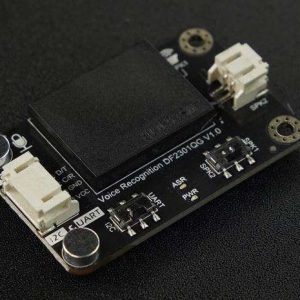

Original price was: $55.00.$19.00Current price is: $19.00.

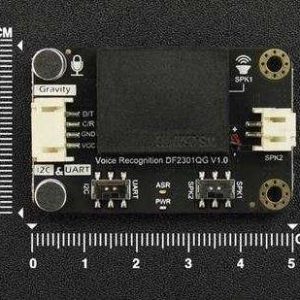

Original price was: $75.00.$29.00Current price is: $29.00.

Original price was: $37.00.$29.00Current price is: $29.00.

Original price was: $799.00.$577.00Current price is: $577.00.

Recent Products

View more